Don't miss our holiday offer - 20% OFF!

The Internet of Things (IoT) has become a central theme in the digital transformation of various sectors. With the ability to connect devices and systems, IoT opens up new opportunities for efficiency, innovation, and better management. In the context of the manufacturing and logistics sectors, the implementation of IoT allows companies to enhance productivity, respond rapidly to market needs, and optimize their overall operations. This article will explain how IoT drives transformation in the manufacturing and logistics sectors, as well as the benefits and challenges faced during this process.

Contents

What is IoT?

Definition

Internet of Things (IoT) refers to a network of physical devices connected to the internet, allowing them to collect and exchange data. Examples include temperature sensors, cameras, and other smart devices that can communicate with each other.

How IoT Works

IoT operates by connecting these devices to the internet and enabling them to work complementarily. When one device collects data, the information can be immediately evaluated and used to optimize broader processes.

Why is IoT Important for the Manufacturing Sector?

1. Increased Production Efficiency

IoT enables real-time monitoring of costs and production processes. Through installed sensors, companies can identify bottlenecks and optimize production lines, resulting in faster and better product output.

2. Process Automation

With IoT applications, many processes that were previously done manually can now be automated. This not only reduces the likelihood of human error but also accelerates operational processes.

3. Early Problem Detection

IoT infrastructure allows for real-time monitoring, which helps detect problems earlier. If a machine shows signs of malfunction, automated notifications can alert technicians to take corrective action immediately.

4. Streamlined Inventory Management

IoT assists companies in monitoring their inventory more effectively. Automated systems can notify management when supplies begin to dwindle, avoiding shortages that could disrupt production processes.

The Role of IoT in the Logistics Sector

1. Route Optimization

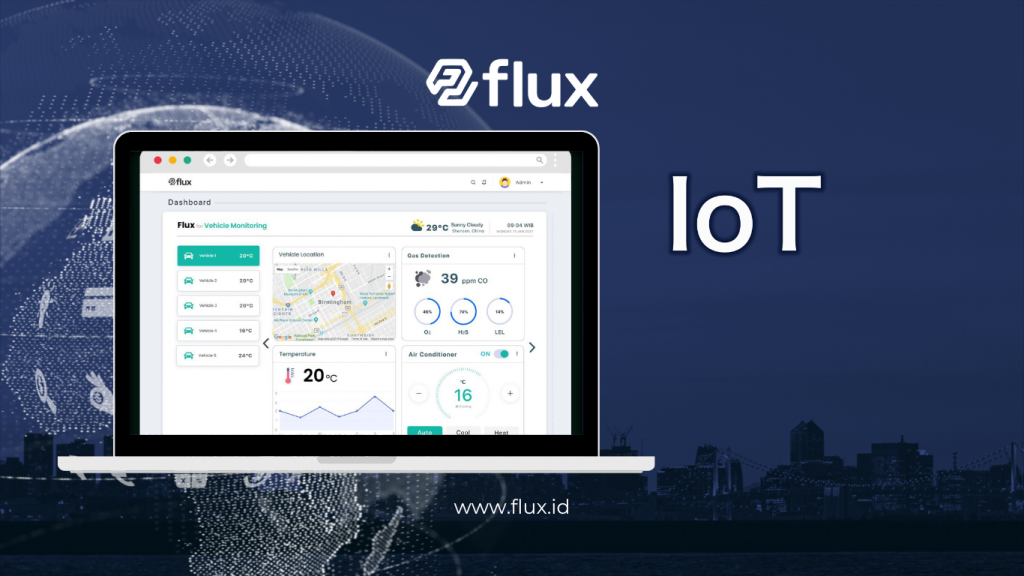

In the logistics sector, IoT is used to monitor vehicle fleets in real-time. GPS data and sensors can be utilized to optimize delivery routes, reducing transit times and fuel costs.

2. Improved Supply Chain Management

IoT allows various stakeholders in the supply chain to share data, enhancing transparency and collaboration. This helps companies manage resources more efficiently.

3. Shipment Condition Monitoring

With sensors mounted on containers, companies can monitor temperature, humidity, and other conditions during shipping. This is crucial for sensitive items like food and pharmaceuticals.

4. Analytics for Continuous Improvement

Data collected from logistics processes can be analyzed to find ways to improve service and efficiency. By using analytics, companies can formulate new strategies to maintain a competitive edge.

Benefits of IoT Implementation in Industry

1. Cost Savings

One of the primary benefits of IoT implementation is cost savings. By enhancing efficiency and reducing waste, companies can save resources and money.

2. Improved Service Quality

With the capability to monitor and analyze performance in real-time, companies can provide better services to customers. Responses to customer inquiries become quicker and more accurate.

3. Continuous Innovation

Companies adopting IoT technology have a better opportunity to innovate their products and services. With insights derived from data, companies can develop new solutions to meet changing market needs.

4. Sustainability

By minimizing waste and optimizing resource utilization, IoT technology contributes to sustainability policies that are increasingly important in today’s business world.

Implementing IoT and Flux in Manufacturing and Logistics Sectors

1. A Clear Implementation Plan

Establishing a clear implementation plan is a crucial first step. This plan should include needs analysis, identification of monitoring points, and the arrangement of necessary hardware.

2. Employee Training

Training for employees who will use IoT technology is essential. With a good understanding, employees can maximize the effectiveness of the implemented systems.

3. Monitoring and Adjustment

Once implemented, it’s important to monitor system performance regularly. Gathering feedback from teams and conducting evaluations will help improve the implementation of IoT systems.

The Future of IoT in Manufacturing and Logistics

1. Integration of Artificial Intelligence (AI)

Artificial intelligence will increasingly dominate IoT applications, allowing for deeper data analysis and faster decision-making. Companies that are ready to integrate AI with IoT will gain a competitive advantage.

2. Smart Factories and Smart Logistics

With widespread adoption of IoT technology, the future will witness the development of fully integrated smart factories and smart logistics. The use of automated systems will bring innovation in how factories and supply chains are managed.

3. Focus on Sustainability

With the increasing focus on sustainability, the application of IoT in the industry will prioritize more environmentally friendly practices, helping companies meet customer demands and regulations.

Conclusion

Internet of Things (IoT) plays a crucial role in redefining how industries operate in the Industry 4.0 era. With innovations from Nocola, companies can take smart steps toward better automation, improve operational efficiency, reduce costs, and provide better services.

Implementing this technology is a strategic investment that not only addresses current challenges but also prepares companies for a more sustainable future. Let’s embrace the new era together with smarter technologies!