Don't miss our holiday offer - 20% OFF!

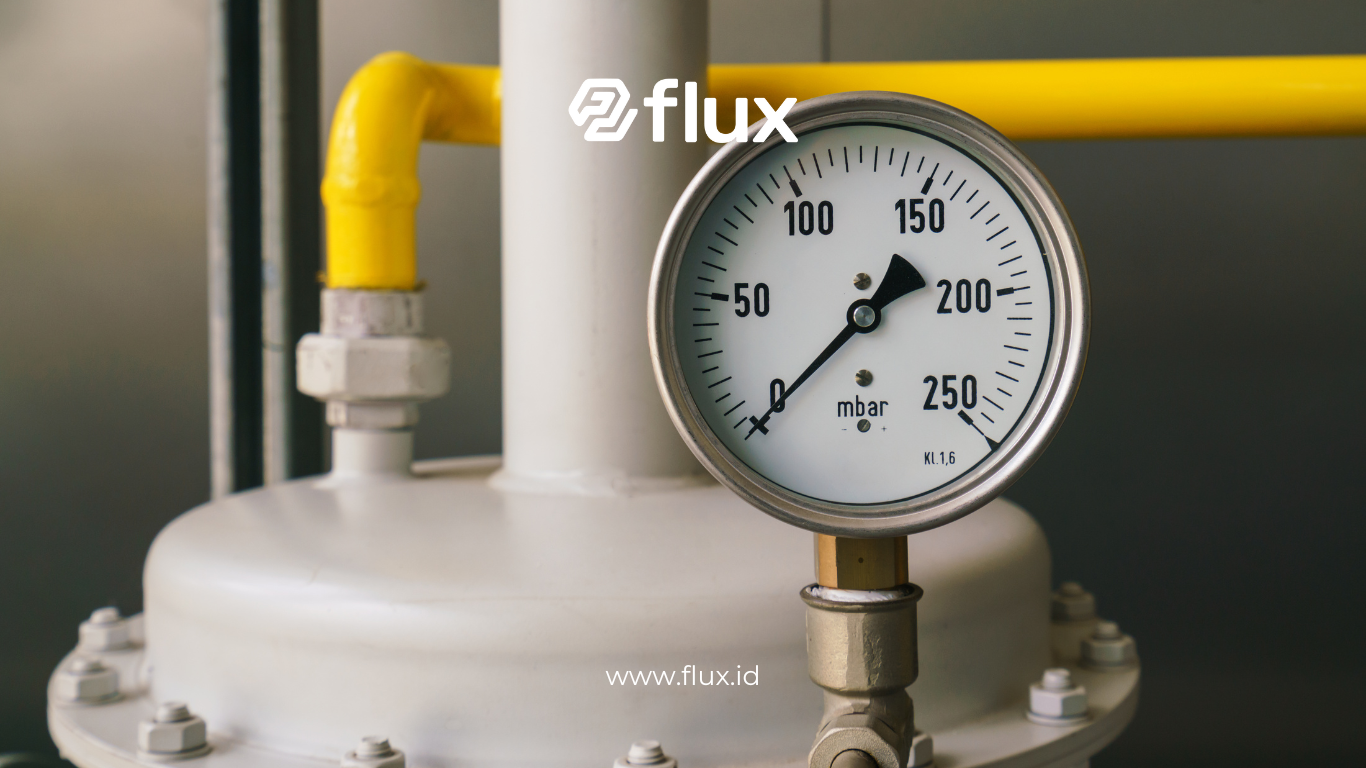

Pressure sensors have become essential components across various industrial sectors. Companies in industries such as automotive and energy management rely on this technology to ensure efficiency and safety. With the ability to detect pressure changes, these sensors provide real-time data that enhances overall process control. In this article, we will explore the vital role of pressure sensors in modern industry and the technological advancements that have revolutionized their application.

Contents

- 1 What Is a Pressure Sensor?

- 2 The Role of Pressure Sensors in the Automotive Industry

- 3 The Role of Pressure Sensors in Energy Management

- 4 Pressure Sensors in the Manufacturing Industry

- 5 Challenges and Innovations in Pressure Sensor Technology

- 6 Benefits of Pressure Sensors in Modern Industry

- 7 Conclusion

What Is a Pressure Sensor?

Read More: Water Pressure Sensor: Boosting Tsunami Warning Reliability

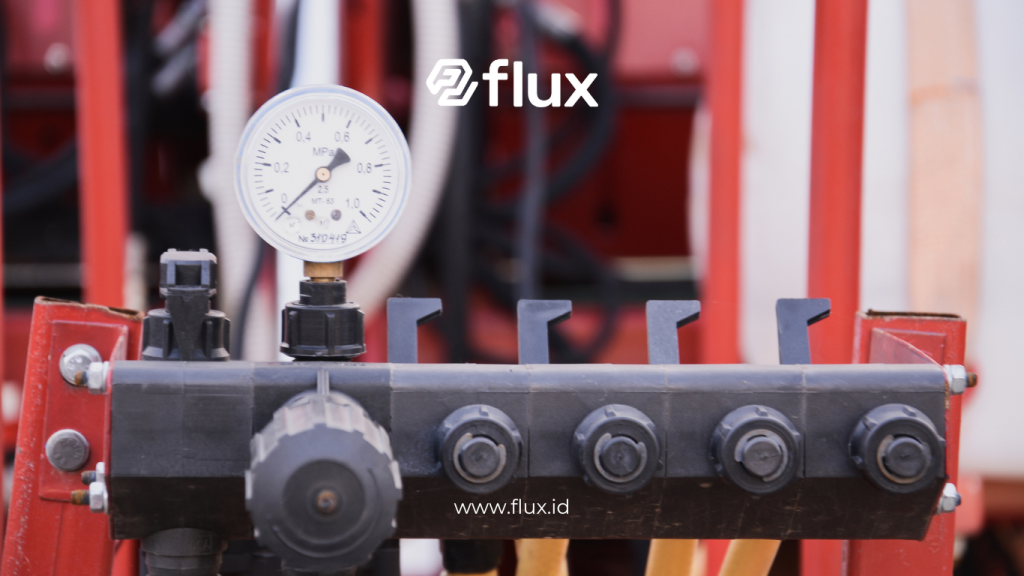

A pressure sensor measures the pressure of gases or liquids and converts the data into an electrical signal. Control systems analyze this information to regulate operations efficiently. Various industries, including automotive, energy, and manufacturing, benefit from this technology in their daily processes.

How a Pressure Sensor Works

Pressure sensors operate by converting physical energy into electrical signals. Different types of sensors exist, such as piezoelectric, strain gauge, and capacitive sensors, each using a unique mechanism. However, their common goal remains the same: to measure pressure changes and transform them into signals that control systems can interpret and respond to.

The Role of Pressure Sensors in the Automotive Industry

Read More: Decoding Pressure Sensors for Flood Prediction and Mitigation

Pressure sensors play a crucial role in maintaining vehicle performance and safety within the automotive industry. For example, in hydraulic brake systems, sensors monitor pressure levels to ensure optimal braking power. Similarly, emissions control systems depend on these sensors to track engine pressure, ultimately reducing harmful exhaust emissions.

Tire Pressure Monitoring System (TPMS)

In addition to engine management, the Tire Pressure Monitoring System (TPMS) uses sensors to provide real-time tire pressure data. Drivers receive alerts if tire pressure drops below a safe level, allowing them to address the issue before it leads to more significant damage, such as a tire blowout. This enhances vehicle safety and extends tire life.

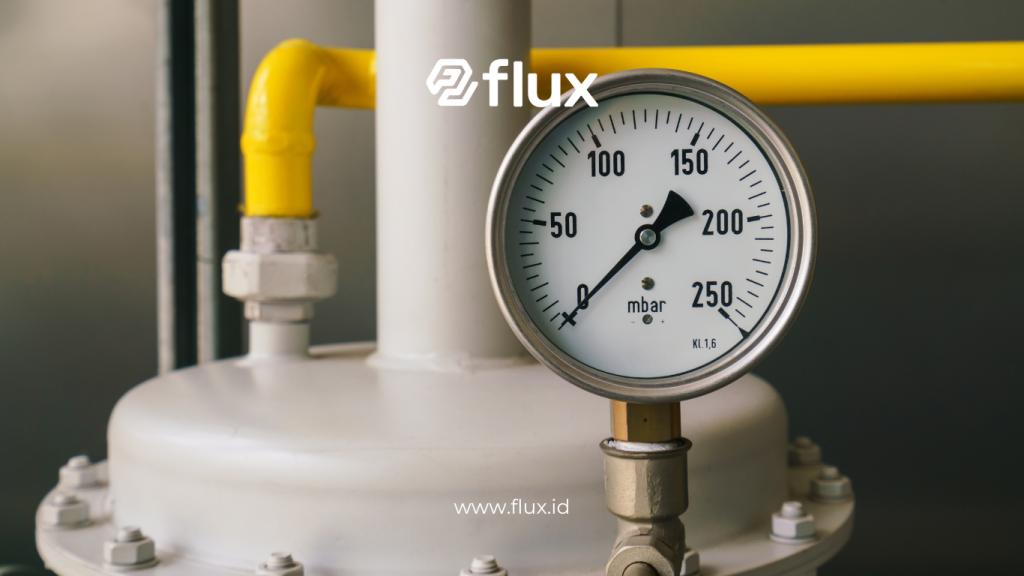

The Role of Pressure Sensors in Energy Management

Read More: How Energy Sensors Revolutionize Building Energy Management

Pressure sensors are just as valuable in energy management, especially in systems that distribute gas and liquids. For example, in power plants, water treatment facilities, and HVAC systems, sensors track pressure in real-time. By doing so, they reduce the risk of leaks and optimize overall efficiency, leading to lower maintenance costs.

Pressure Sensors in HVAC Systems

HVAC systems use pressure sensors to regulate airflow and coolant circulation. Effective monitoring allows HVAC systems to run more efficiently, ultimately reducing energy consumption. Furthermore, sensors quickly detect any abnormal pressure levels, signaling potential issues within the system so that maintenance can be performed before more significant problems arise.

Pressure Sensors in the Manufacturing Industry

In manufacturing, pressure sensors serve multiple functions, including process monitoring and product testing. On production lines, they ensure that machinery operates within optimal parameters. Additionally, these sensors play a critical role in quality control, especially in industries that require high precision, such as medical equipment and packaging.

Application of Pressure Sensors in Product Testing

Pressure sensors are vital in product testing, particularly for leak detection. During tests, the sensors track pressure changes within products, ensuring no leakage occurs. This is especially important in packaging and medical equipment manufacturing, where even minor leaks could lead to product failure or health risks.

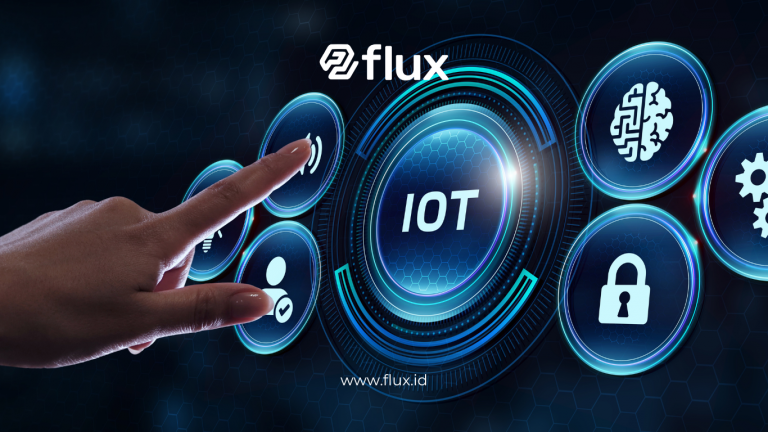

Challenges and Innovations in Pressure Sensor Technology

Read More: Latest Innovation: High Water Sensors for Early Flood Detection

Despite their widespread use, pressure sensors face technical challenges, especially regarding accuracy and durability in extreme conditions. Nevertheless, technological advancements continue to improve their reliability. One such innovation is the integration of pressure sensors with the Internet of Things (IoT), which enhances real-time monitoring and data analysis capabilities.

Pressure Sensors and the Internet of Things (IoT)

IoT integration elevates the functionality of pressure sensors. Users can access pressure data from remote locations, receiving real-time updates on system performance. This feature is especially beneficial in energy distribution and manufacturing sectors, where rapid responses to pressure changes are critical. Additionally, connecting sensor data to cloud-based management systems enables faster and more detailed analyses.

Benefits of Pressure Sensors in Modern Industry

Read More: Revealing the Role of Accelerometers and Gyroscopes in Modern Devices: From Smartphones to Drones

Pressure sensors offer several key benefits, including increased efficiency, reduced risk, and enhanced safety. In the automotive sector, they contribute to vehicle performance optimization and emissions reduction. In energy management, they allow for more effective monitoring, lowering the risk of leaks and improving operational efficiency. In manufacturing, pressure sensors ensure smooth operations and consistent product quality.

Efficiency and Cost Savings

Real-time pressure monitoring helps identify issues early, enabling swift repairs before major problems occur. As a result, operational efficiency increases while maintenance costs and downtime are minimized. Companies can also optimize resource use, leading to significant cost savings.

Operational Safety

Pressure sensors also enhance safety in critical sectors such as energy and chemical industries. By continuously monitoring pressure levels, they help prevent accidents that could endanger workers and the surrounding environment.

Conclusion

Pressure sensors have brought significant improvements across various industries. Whether in automotive, energy management, or manufacturing, this technology plays a vital role in optimizing efficiency and safety. As advancements like IoT continue to evolve, the impact of pressure sensors will only grow. Current challenges will likely be addressed through ongoing innovation, making pressure sensors increasingly essential in modern industry.